Tertiary amine and imidazole: 2 epoxies

发布时间:2019-10-30 15:15

usually use amine epoxy resin and anhydride curing agent is heated and get cured product of crosslinked structure, anhydride curable epoxy resin and high curing temperature and long curing time, to save energy and shorten the production cycle, need curing catalyst is added to the system. Good anhydride curing epoxy resin with promoter should not affect system performance, low temperature (room temperature) of cured product of low reactivity, high temperature reactivity is bigger, it has good compatibility with anhydride/epoxy resin system. At present, such promoters mainly include tertiary amine and imidazole. It is introduced that the temperature storage period of the tertiary amine/acid anhydride/epoxy system is introduced, and the carboxylation of tertiary amine is one of the effective methods.

Tertiary amine is a type of nucleophilic stimulant, which can be used to catalyze both epoxy and acid anhydride. China epoxy resin industry association (www.epoxy-e.cn) expert says, the domestic industry has recently studies triethanolamine, dimethyl aniline and DMP - 30 several tertiary amine to promote properties of acid anhydride/epoxy system, the results showed that dimethyl aniline hydrogen, DMP - 30 and methyl benzene anhydride has good compatibility, dimethyl aniline reactivity but low temperature viscosity rise speed is fast; In DMP - 30, the high temperature reaction activity is larger, and the viscosity of the normal temperature increases slowly but is slower. The characteristic of DMP -30 is related to the molecular space structure with the larger resistance. The study of the mechanical and electrical performance test and the scanning electron microscope showed that the quality score of DMP -30 was 0.5% to 2.0%, and had no obvious effect on the properties and micromorphology of the solidified material.

In order to prolong the temperature storage period of the tertiary amine/acid anhydride/epoxy system, the modification of tertiary amine is one of the effective ways to resalinize carboxylic acid. With DMP - 30 3-2 - ethyl caproate promoter, four of epoxy/liquid methyl hydrogen of benzene anhydride system latent and curing reaction kinetics study results show that the system response series is 0.905, the reaction activation energy of 65.03 kJ/mol, longer than promotion system of DMP - 30 could system at room temperature, high temperature and the reaction rate is greater than the promotion system of DMP - 30 with concentration. Studies suggest that DMP - 30 through rechlorination to reduce the electron cloud density on the tertiary amine nitrogen atoms, thus reducing its curing reactivity, slowly in the room temperature in accordance with the following mechanism to promote anhydride and the reaction of epoxy group. When the temperature higher than 120 ℃, the double salt dissociation into tertiary amine, and carboxylic acid, promotion system of tertiary amine and carboxylic acid and the curing reaction. Because of this double promotion, the reaction activity of the carboxylic acid compound in the high temperature is greater than that of tertiary amine. The carboxylic acid compound of tertiary amine is compatible with epoxy/anhydride system, and there is no obvious difference between the electric performance of the solidified product and the tertiary amine system.

About imidazole and imidazole salt promoter, China epoxy resin industry association (www.epoxy-e.cn) experts say: imidazoles lively molecular structure of compounds containing secondary amine hydrogen atoms, itself can be temperature curing agent for epoxy resin, at the same time there are tertiary amine nitrogen atoms in its molecules, also can be used as acid anhydride/epoxy resin system of karyotype promoter. In order to develop a new type of automobile ignition coil filling, domestic researchers have developed a kind of imidazol compound used as a curing promoter for epoxy/acid anhydride system. The compounds in the system of curing reaction promoting effect is good, the solidifying product thermal deformation temperature of 135 ℃. Imidazoles are mostly melting crystals with poor compatibility with liquid acid anhydride, and imidazole activity can greatly shorten the life of the system.

Someone of imidazole modification have been researched, and found that when some transition metal halide, sulfate, nitrate and imidazole, the molar ratio of 1:4 can synthesize a kind of imidazole salt complex. This kind of complex can reduce the normal temperature reaction activity by sealing up the tertiary nitrogen atoms in midazole by the complexation of metal ions and nitrogen atoms. When the temperature is increased, the complex structure dissociates, and the dissociated imidazole can significantly promote the curing of the acid anhydride system. And researchers synthesized NiCl2 - Im, CuC12 - Im, CuBr2 - Im for imidazole (Im) three imidazole salt, and studied their four hydrogen in the liquid methyl benzene anhydride as curing agent, the results showed that 25 ℃ after 20 d system viscosity only increased by 24%. By measuring the curing curves show that the system in three kinds of imidazole salt, high temperature with high reaction activity but smooth, without sharp exothermic phenomenon, electrical and mechanical performance of the product and promotion system of imidazole curing the same.

上一篇:The United States intends to amend the allowable limits of glyphosate, wild and imidazolone

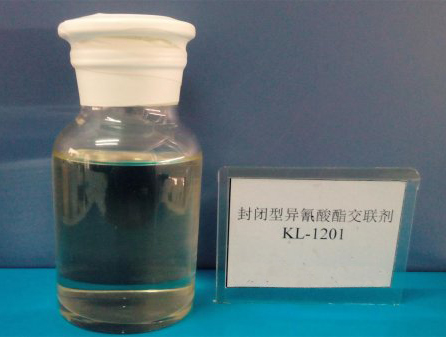

下一篇:Rectification scheme for sewage pipe network of mingpin company

推荐文章

-

Tertiary amine and imida...

Tertiary amine and imida...

usually use amine epoxy resin and anhydride curing agent is ...

-

The fine chemicals show ...

The fine chemicals show ...

At present, due to the escalation of the debt crisis in Euro...

-

The two cola promised to...

The two cola promised to...

The caramelization of the caramel pigment will promote the p...

-

Rectification scheme for...

Rectification scheme for...

Rectification scheme for sewage pipe network of mingpin comp...

-

The United States intend...

The United States intend...

On July 21, 2009, the United States issued a notice to revis...

-

Environmental protection...

Environmental protection...

Environmental protection plan